Ocular prostheses - the perfect alternative to the eyeball

Modern medicine helps those who have completely lost an eyeball as a result of an accident or illness to overcome discomfort caused by their disability. This is possible due to modern 3D printed ocular prosthesis, precisely tailored to Patients’ expectations. When we talk about a modern ocular prosthesis, we mean a prosthesis that not only looks realistic, but is also durable and comfortable to wear; it is made of innovative biopolymers created individually for each Patient with the highest precision never achieved before. This is exactly what we offer to anyone who visits our Chorzów location, asking for help. Our ocularist meticulously selects prostheses according to Patients’ individual physiognomic and anatomic features, which guarantees the best results. Then he/she produces a Next Eye prostheses, which have numerous advantages.

Characteristics and advantages of Next Eye prostheses

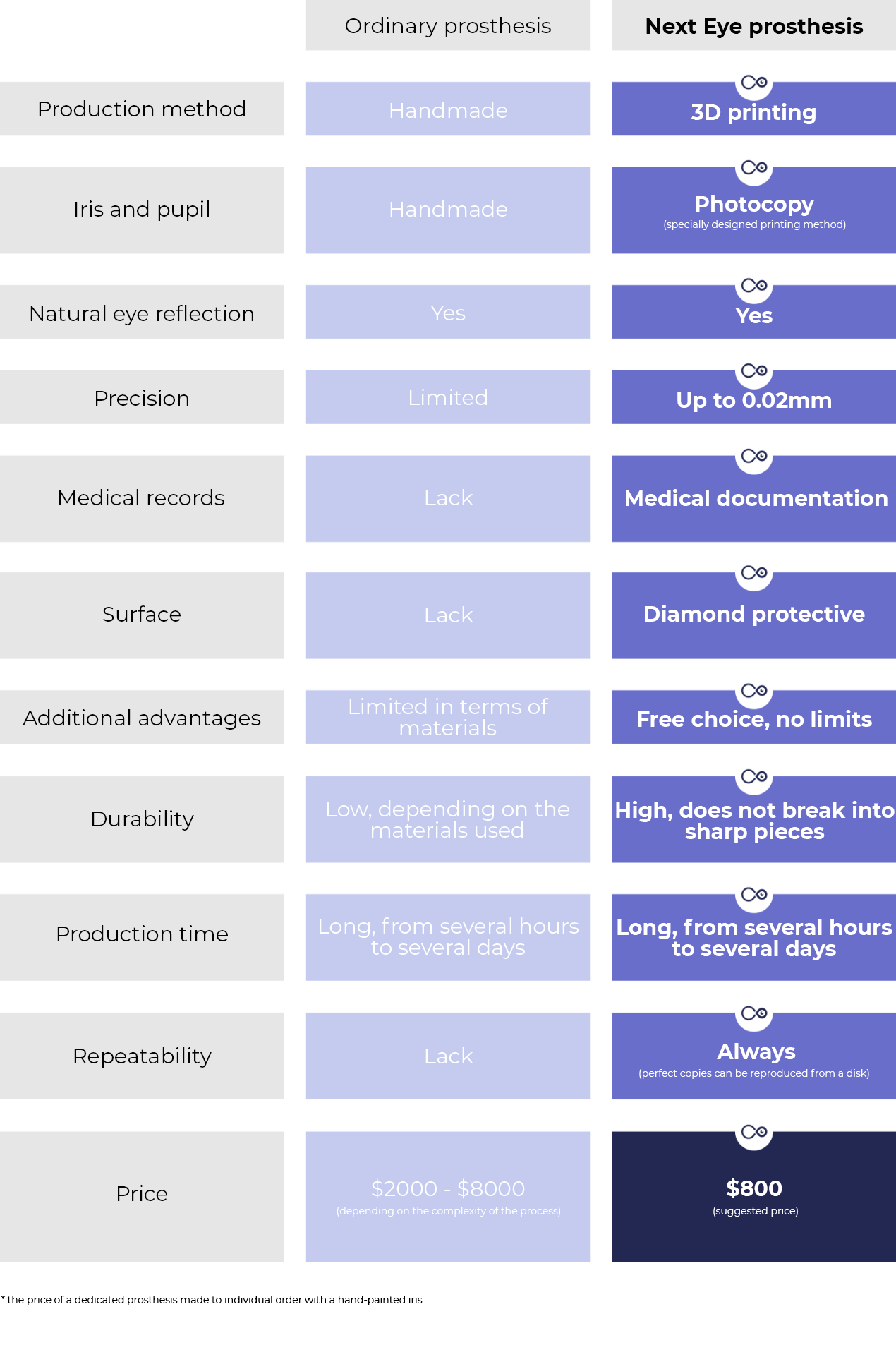

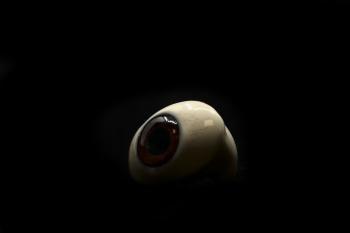

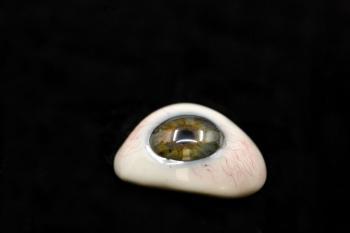

The most important feature of Next Eye prostheses is high precision of workmanship, in terms of both technical and aesthetic qualities. Next Eye prostheses are made of biocompatible polymers coated with a diamond protective layer, which prevents deposition of secretions. This coating does not turn yellow or fade, which may happen in case of acrylic prostheses. Thanks to the polymers used, Next Eye prostheses are much more durable than glass ones. There is no risk that this prosthesis will break into small, sharp pieces. The products have a natural eye reflection, thanks to which the eyeball made by an ocularist looks genuine. Besides, we can use polymers to produce a partially or fully removable ocular prosthesis.

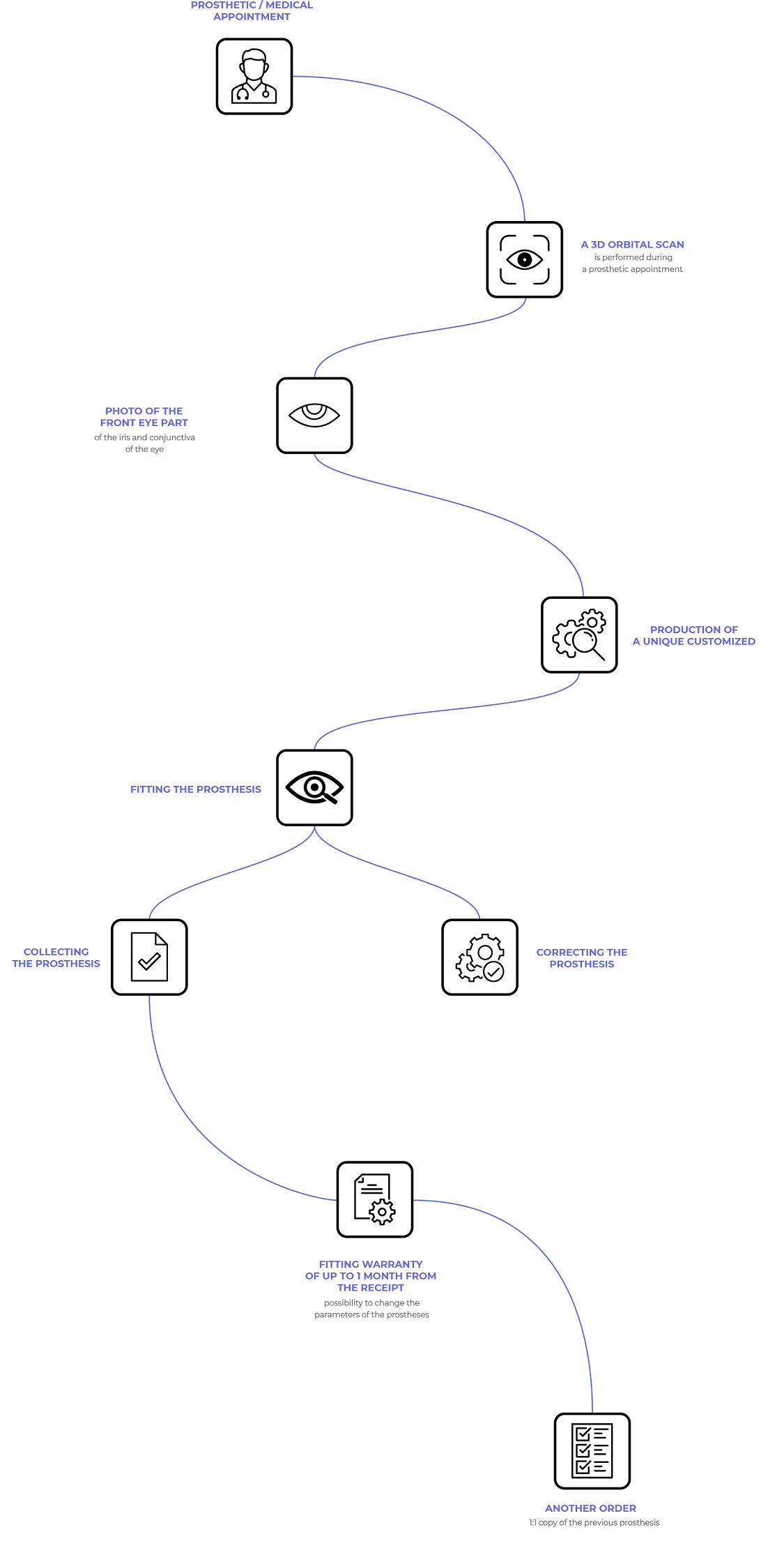

Next Eye prostheses and epiprostheses are produced, using the additive manufacturing method with 3D printing technology. Ocular prosthesis is selected based on digitally collected data: a 3D orbit scan and an iris photo of the other eye. As a result, the prosthesis perfectly imitates the orbit. Another notable aspect is very high comfort of using the product, as it reflects all the anatomical details of the orbit.

Production of another ocular prosthesis

The iris and pupil are photocopied, using a specially designed printing method, which results in a perfectly natural reproduction. All the materials used in the production process are certified, which means that they are safe for the body. In the future, the prosthesis can be made again, retaining all the features of the previous one, as the data is collected in a specially secured archive. We also have a database of ready-made prostheses.

PL

PL  EN

EN  UA

UA  DE

DE  ES

ES  IT

IT